In the world of premium wine tasting, a glass is more than just a vessel—it is the ultimate signature of brand identity. At Perfect Select Ltd, we specialize in the “impossible”: delivering ultra-thin, artisan-blown glassware with the precision of modern engineering.

1. The Collaborative Process: Design-First Engineering

We don’t just take orders; we audit designs to bridge the gap between artistic vision and technical reality.

-

Step 01: Industrial Feasibility & Consultation Our in-house designers provide professional feedback on wall thickness and structural integrity to ensure your concept survives the furnace without losing its aesthetic soul.

-

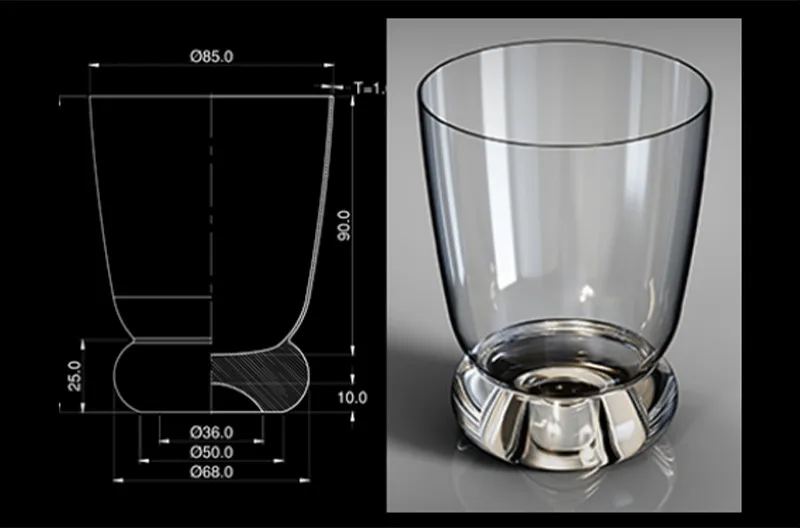

Step 02: High-Fidelity 3D Visualization Eliminate the guesswork. We provide hyper-realistic 3D renders that simulate light refraction and material clarity. Evaluate your branding and silhouette digitally before a single mold is cast.

-

Step 03: Rapid Prototyping From digital render to physical sample. Our rapid prototyping service allows for swift adjustments, ensuring the final weight and “hand-feel” perfectly align with your expectations.

Ready to elevate your brand with ultra-thin crystal? Contact us to discuss your bespoke requirements and get a professional quote.

2. The Manufacturing Standard: The 0.06mm Benchmark

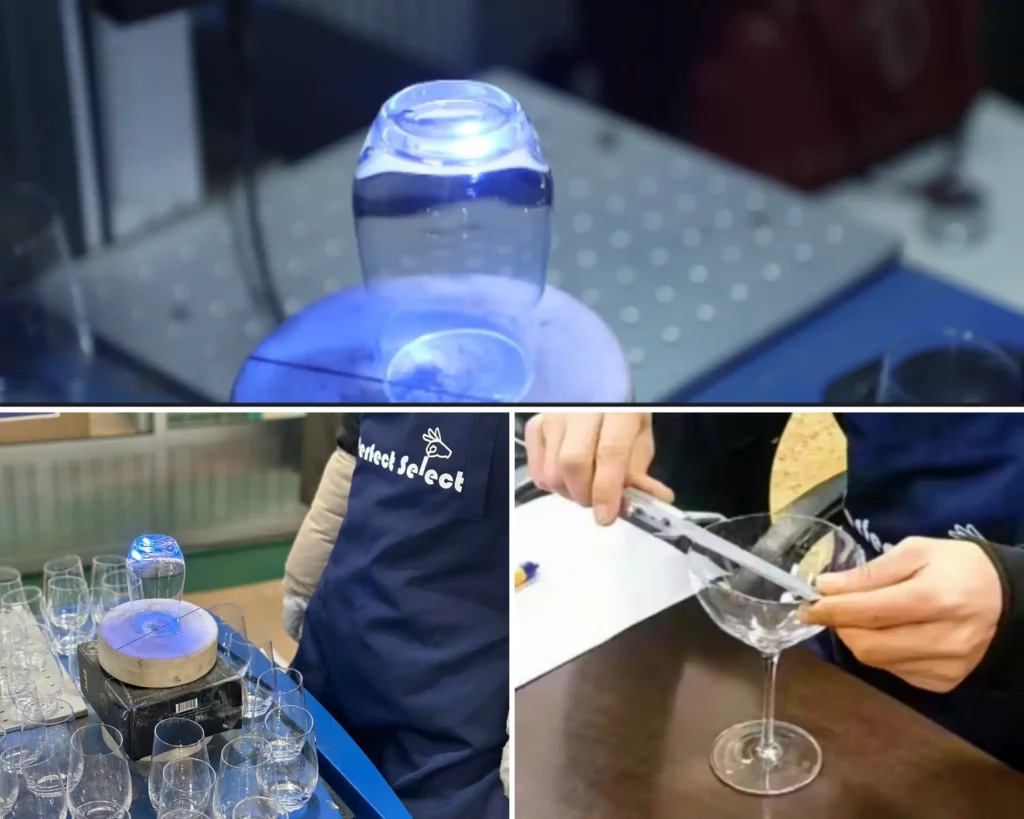

While machines provide volume, only the human breath can achieve the Perfect Select Standard. Our facility leverages top-of-the-line machinery managed by highly-skilled technicians to ensure efficiency and quality.

-

The 0.06mm Ultra-Thin Rim: Utilizing laser-cut and diamond-polishing technology, we achieve a rim thickness of 0.06mm – 0.07mm. This “invisible” edge ensures an unobstructed flow of wine to the palate.

-

The 100g Silhouette: By optimizing the distribution of lead-free crystal, our glasses achieve a slender 3.5mm body, resulting in a feather-light weight of approximately 100 grams.

-

Lead-Free Crystal Composition: Our raw materials are strictly compliant with European safety standards, offering superior acoustic resonance and diamond-like clarity.

3. Quality Management: Stability in Every Batch

Artisan craftsmanship does not have to mean inconsistent quality. We implement a rigorous Integrated Quality Loop to maintain excellence.

-

Multi-Point Inspection: From rim uniformity to upright balance, our QC team manually inspects every piece at three separate stages to ensure material consistency.

-

Bulk Consistency: We guarantee that your 5,000th glass is identical in weight, clarity, and dimensions to the first approved sample.

4. Seamless Customization Process: How to Work With Us

We have established a standardized collaborative process designed to transform your design concepts into high-quality, mass-producible products.

-

Step 01: Requirement & Vision Confirmation: Send your initial ideas, sketches, or CAD drawings via WhatsApp or email. We will gain a deep understanding of your brand positioning, application scenarios (such as five-star hotels, high-end wineries, or retail channels), and target order volume.

-

Step 02: Design Optimization & 3D Review: Our design and engineering team will conduct an industrial review of the drawings. We will provide professional suggestions for modifications from aspects such as glass thickness, center of gravity balance, and rim curvature, and simultaneously provide 3D rendering materials for your initial visual verification, ensuring that the solution is both aesthetically pleasing and mass-producible.

-

Step 03: Prototyping & Transparent Quoting: After the design is confirmed, we enter the physical prototyping stage. We will provide you with a precise quotation (including mold costs and unit price for mass production). You can personally test the transparency, weight, and feel of the cups using physical samples to ensure that every parameter meets your brand standards.

-

Step 04: Production & Global Logistics: After sample confirmation, mass production officially begins. Each batch of products undergoes our “three-stage quality inspection cycle.” Finally, we use shock-resistant packaging specifically designed for ultra-thin crystal glass and arrange global logistics to ensure that your custom-made cups are delivered safely and on time to your warehouse or hotel.

Start Your Project Today

Ready to redefine your brand’s tabletop experience? Our team is standing by to provide a Free Design Feasibility Review and a transparent quote for your next collection.

-

WhatsApp Consultant: +66 80 637 2080

-

Email Technical Team: lillian@perfectselect.cn

Post Comment